The lead EVs of the future will be powered by chips, and the demand for chips in EVs will rise as more people choose them. The chip industry is currently struggling due to a shortage of silicon. However, with the success of Tesla EVs, the chip shortage will no longer be an issue. The company will be able to source its components directly from chip manufacturers. It will also be able to obtain long-term volume contracts with multiple manufacturers.

Reduce the overall cost of the car’s wiring

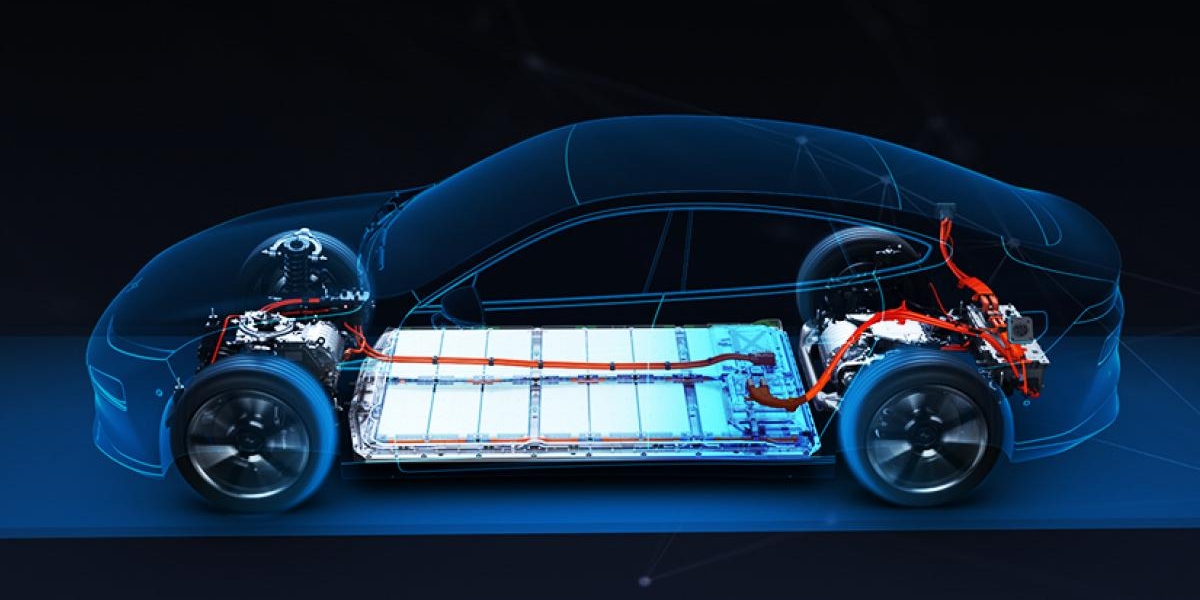

A significant development in the chip industry is the 800V DC bus. This bus will increase the power available to the vehicle and other applications while reducing the size of the electrical connectors. This new technology will reduce heat and losses in the semiconductors, which will reduce the overall cost of the car’s wiring. SiC’s high-voltage capability is ideal for EVs and other applications, and the technology is already available in consumer products like laptops.

Make it easier to develop more advanced electric vehicles

The chip industry is also making progress on the power electronics of electric vehicles. For instance, small inverters and silicon carbide contribute to the reduction of power components. This new material has been the favorite of the semiconductor industry for decades, but EVs are chipping away at its dominance. The technology behind these cars is advancing rapidly and will continue to impact the chip industry. This will eventually make it easier for manufacturers to develop more advanced electric vehicles.

Reduce the cost of manufacturing

The chip industry is also developing more efficient components. The chips used in EVs are much smaller than those used in cars today. In addition, they feature silicon carbide that can dissipate heat. This new technology will help improve the efficiency of electric vehicle power electronics and reduce the cost of manufacturing. The silicon-based semiconductors are the main components in the electric vehicles, and they have dominated the chip industry for decades.

SiC chips for batteries in electric vehicles

Silicon carbide chips will be used in the Tesla EVs as a way to enhance battery performance and reduce air resistance. The silicon-carbide chips are also used in LED lights. This new technology will be used in the car’s interior. The LED light bulbs in the EVs will have a lower air resistance factor than conventional LED bulbs. The battery in EVs will be fitted with the SiC chips.

SiC chips are also being used in the EVs’ power electronics. Many EV manufacturers are already using SiC chips in their EVs. The silicon-carbide chips are particularly efficient at handling high voltages, which makes it perfect for electric vehicles. The silicon-carbide technology is a major factor in driving the electric vehicle industry. This technology will also help in lowering the cost of batteries.

Although the chip industry has been mostly concerned with the production of silicon-based devices, the EV market has been largely untapped. The silicon-carbide chips are especially adept at handling higher voltages. As a result, the EV industry is seeing a resurgence in the chip industry. It is the first big market for silicon-carbides and the electric vehicle manufacturing companies are focusing on making the chips that are needed to make this technology a reality.

The silicon-carbide chips in the Tesla Model 3 are made of silicon carbide. The silicon-carbide material is also better at dissipating heat, and it is widely used in inverters. Furthermore, this technology is a big boon to the semiconductor industry. In addition, it also helps chip away at silicon’s dominance in the semiconductor industry. So, the lead EVs are helping to power the chip industry.

In addition, the SiC chips are more efficient than silicon, and they are able to dissipate heat well. The inverter is the device that controls the flow of power to the motor. It will also control the voltage and battery voltage of the EV. With these two improvements, the inverter and the battery are more energy-efficient. It will make the EVs more efficient.