Plastic mold manufacturing, as you have learned in the previous series, is a critical manufacturing process used to produce various components and pieces. These include intricate parts and large sections. And although plastic injection molding is still evolving because of the revolutionary technological advancements, the process is still fundamentally the same in the long run. This article provides a short history of plastic injection molding and projections for the future.

The Preface

Today’s forms of plastic injection molding processes are items produced by computer-generated formulas and managed then injected into the metal to form custom plastic-named dishes. Plastic injection molding items also inject hot plastic into a molten while cooling the plastic and extracts from different components. The molding tools make mass production simple and easy.

The plastic injection molding processes of the current era are versatile and efficient. This implies that it is easy to produce various commodities at once.

Multiple plastic materials-representing different melting points provide special advantages coupled with benefits for certain applications.

Many come with specialized applications. Modern plastic may also be merged with other top-notch materials to provide manufacturers with features, coloring, and applications. Some of the common versatile plastics in use include ABS, nylon, HIPS, and PVC.

Molds and Machines

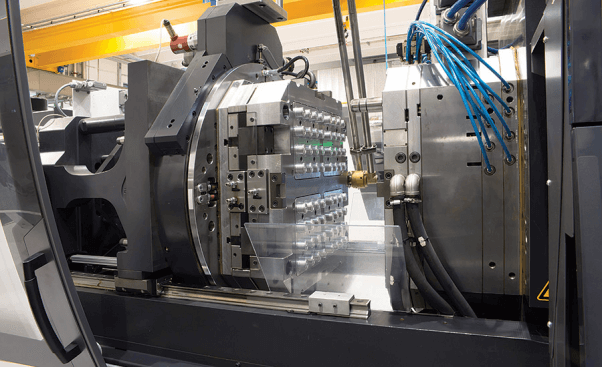

Conventionally, molds would use PIM with two places. One plate has a cavity while the second one came with a core. On the other hand, computer-assisted manufacturing is currently used in producing modern molds, which may significantly be more intricate than the two-plate predecessors with several parts.

And although the mold cavities mentioned earlier above are the primary components of mold making, today’s molds are designed to precise specifications, thereby allowing higher complexities within the molded products.

The Future

Manufacturing took a transition in 1946 when Mr. James Hendry, the famous American inventor, built the original crew injection machine. The screw injection machine offered greater control over the total speed of plastic injection. This improves product quality.

Hendry’s machine allowed the mixing of materials during injection to blend in color. He decided to refine the concept to enhance production. Towards that end, he introduced a gas-enabled machine to the screw of the device. The tool was ideal for the design and development of complicated and hollow pieces that required lesser cooling time and the standard components.

Gas-assisted injection machines also appealed to the manufacturers who need a cost-effective solution to handle complex pieces that provided unmatched strength.

Preview at the Future

Looking at the future of plastic mold injection, advances in technologies, and the continuous development of improved materials are evident. Critical shifts in the plastic industry are currently occurring as well as shaping the future.

Bottom Line

Improved and light-weight components are relatively reducing the costs of production and streamlining processes. Tailored features are currently allowing manufacturers to make use of precision technology in creating top-notch quality products. Apart from that, increased awareness and knowledge dissemination of climatic changes, as well as other environmental elements, will still drive demand for eco-friendly materials like recycled and reclaimed products.