Fiber laser welding is everything about control of the procedure, according to Kurt Magedanz, laser process engineer at Ace Precision Machining Corp., Oconomowoc, Wis. With its brand-new Laserdyne 430 systems, Ace Precision has made huge strides with weld quality while lowering operator treatment in the process.

Ace Precision Machining is AS9100 Certified as well as a worldwide acknowledged vendor to the aerospace, power generation and also protection markets, providing substantial manufacturing capabilities encompassing all areas of steel construction, joining and also layer. It has experience with several generator engine styles, including armed forces systems for Apache as well as Chinook Helicopters, Abrams M1 Battle Tanks, as well as B2, F18, F22 as well as F35 airplane. When Ace Precision initiated a brand-new welding procedure on one of its 2 lately acquired Laserdyne 430 fiber laser systems, the firm’s laser welding capacities lately took center phase.

Development of fiber laser welding is occurring rapidly. New refines spearheaded by Prima Power Laserdyne, Champlin, Minn., as well as now adopted by Ace Precision, become part of that growth. Conventional welding techniques, still prevalent in today’s production, call for significant driver focus to regulate weld top quality. With the power currently readily available with a fiber laser and the proprietary integrated Prima Power Laserdyne S94P CNC control, adjustment is underway.

” It’s everything about the quantity of control we have more than the welding procedure currently compared to in the past,” Magedanz stated. “With the earlier process, we utilized a CO2 laser system that didn’t have weld-specific hardware or software program. We experienced significant rework on the bonded settings up as well as required to replace the laser lenses regularly. With only one of the most careful driver interest, we acquired appropriate weld quality up till Prima Power Laserdyne stepped forward with a considerably better system as well as procedure.”

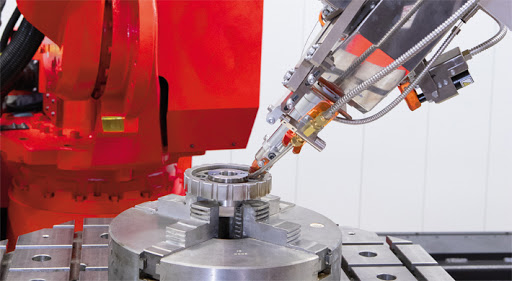

The difficult, two-part welded assembly that influenced this enhanced process was for an army application. With an approximate 12″ (304.8 mm) size final assembly, the crucial welding procedure called for a contoured, overlapping joint weld of a round 0.060″ (1.524-mm) thick Hastelloy X sheet metal part onto a machined Hastelloy X element. Keeping the weld seam consistent in width and also deepness without spaces between both components was vital.

” With our new Laserdyne 430, the S94P laser handling video camera system enables us to determine the precise location of the weld joint on the Hastelloy X material. That permits us to tweak our placement before the welding process begins,” reported Magedanz. He kept in mind that with its old CO2 system, the element fit-up and also fixturing were extra critical to producing regular welds. The new machine controller’s orbiting function, which oscillates (wobbles) the machine axes at a certain regulated dimension and frequency, allows for specific control of the characteristics of the weld joint.

” The brand-new Laserdyne 430 fiber laser system has actually removed virtually all rework of components that we made use of to encounter on the CO2 system, especially at the start/stop point of the weld,” he stated. The particular arrangement of the elements that were bonded locations the weld grain close against the side of the material with little margin for error to avoid melting the edge of the component. “The capacity to specifically control the fiber laser’s setting, focus and power, in addition to the system’s SmartRamp feature, has made it feasible and much easier to manage the laser welding procedure,” he claimed.

” Our previous welding procedure, with its mix of fixturing and setting up requirements, really did not have adequate accuracy to exactly determine truth emphasis setting repetitively,” claimed Magedanz. “The brand-new OFC2 Absolute function has remarkable mapping run-out with the new software application, allowing for precise and also repeatable emphasis positioning.” This feature aids to specifically position focus on the weld joint of every component. The OFC2 Absolute has a longer working array as well as is qualified of measuring component surfaces on an angle no matter of the part surface area condition. “This most current capability enables a wider range of chances for improving existing processes,” Magedanz stated.

Earlier, multi-process laser systems for cutting, boring and also welding were only just “adequate” for welding. According to Prima Power, its brand-new Laserdyne 430s have new functions created for the challenges distinct to welding in addition to supplying exceptional cutting and also exploration. The systems include weld ramping, gas flow control, lens protection and an incorporated air knife that makes the welding process more manageable.

Ace Precision’s new Laserdyne 430 systems, OFC2 Absolute software feature gives much better precision when it maps the weld surface. It does this to maintain the laser light beam focus at the specific location of the laser bonded so there is no variance or spaces in the weld framework. Additionally, OFC2 Absolute has a lengthy functioning variety so that the location of recommendation features such as edges, corners, holes, or various other functions can be figured out utilizing a greater, extra charitable stand-off between the laser processing head and workpiece supplying no disturbance of the process.

While the 20 kW laser on the Laserdyne 430 is most commonly used for piercing and reducing, Prima Power Laserdyne’s exclusive software application permits the laser to be effectively used for welding applications.

The BeamDirector function provides two added axes of motion to the moving table style for the Laserdyne 430. Accuracy welding comes not only from the efficiency as well as precision of the Laserdyne 430 movement system, but additionally from innovative Prima Power Laserdyne SmartTechniques that allow the fiber laser to efficiently carry out a full range of welding jobs, especially Ace Precision’s intricate welding of military components. This is the outcome of incorporated control of the laser, activity and cpus. Precision welding is not just measured by the accuracy and also repeatability of the device tool, yet extra notably by the constant components created on the system.

Both the capacitive and also optical approaches of emphasis control precisely guide the motion system, maintaining critical focus setting and complying with the shape of the component regardless of surface area abnormalities. All linear axes of the system respond to picking up of the part surface, developing unrestricted adjustment along the axis of the light beam. The combination of crash security and component picking up provides the Ace Precision system driver self-confidence to utilize aggressive processing rates feasible without fear of harming the system or ditching the component.

” The weld head itself is one more system attribute we required,” specified Magedanz. “We had actually limited lens defense with the CO2 system we were utilizing. We ‘d full two or 3 part runs and after that require to replace the lens.” The most recent Laserdyne 430 system, with an air blade attribute integrated in its SmartShield, impacts air down and also across the lens to maintain it properly devoid of weld spatter and also debris while cooling the lens. The air blade develops an unseen barrier so pollutants are kept from transferring on the lens. With the SmartShield attributes, welding accuracy is made certain and also expensive lens replacement is minimized with the added benefit of minimizing machine downtime.

Wanting to boost all of its laser operations at a busy time, Ace Precision also obtained a Prima Power Platino Fiber Evo laser system about the exact same time it acquired its two Laserdyne 430 fiber systems. The Platino gives Ace Precision increased performance for its level sheet steel processing with decreased piercing times and enhanced cutting speeds, particularly on thick product.

” Acquiring those three equipments really assisted make our laser procedures more efficient and efficient when we really needed it,” stated Magedanz. “Prima Power is a leader with fiber laser modern technology and offers us with competitive advantages. Getting brand-new fiber systems from the very same manufacturer is efficient, affordable and makes sure a high degree of service continuity that is important to us and our consumers.”

Prima Power Laserdyne is a global developer and provider of commercial precision laser handling systems for 3D welding, drilling, and cutting. Prima Power is additionally a system distributor of sheet steel cutting, bending and automated handling systems.