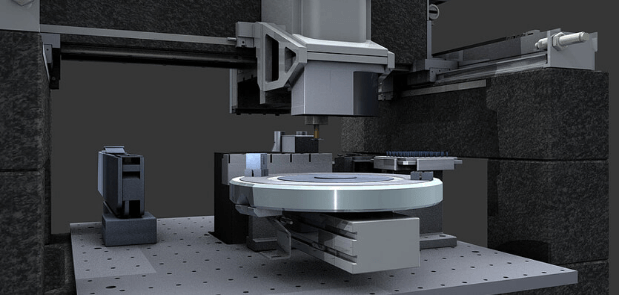

Thanks to advanced industrial technology, you can now dictate the shape of various products during the production process. Precision manufacturing is now a vital process in areas where integrity and dimensional accuracy are of fundamental concern. Precision engineering produces a broad range of objects and proves to be a critical technique in the manufacturing industry. Below are the benefits of precision machining.

- Improved Production Efficiency

Precision engineering relies on automated machines that operate at high speed without human interference. That means less workforce in parts processing, minimal production cost and enhanced product quality leading to improved operational efficiency. But, this demands a professional team that is competent in operating the advanced machinery and systems.

- No Material Wastage

The introduction of advanced precision techniques has reduced material wastage in many companies. Even though some level of waste is expected in the engineering and manufacturing industry, applying precision machining will dramatically reduce wastage. This significantly saves cost in manufacturing industries, conserves the environment and maximizes the use of costly materials. The capability to make use of all your raw materials will reduce your company production cost and realize rapid turnover rates.

- Reduced Lead time

What are the benefits of using an automated technique? Precision engineering entails the use of machines with automatic assembling features. It means manual assembling is not required. Thus, companies will take a shorter time to complete projects and can take in large orders at a given time. Precision manufacturing companies maximize advanced precision techniques to accelerate production. It allows fast turnaround delivery and reliable services for their clients. When production cycles are more rapid, that does not translate to compromised quality. Professional precision engineers will maintain quality in all machining processes to ensure the production of perfect products that meet client expectations. With rapid production and guaranteed quality, you will operate more efficiently.

- Simplified Prototype Testing

Through precision engineering, you can explore small markets with guaranteed high returns. Flexibility in the product-development stage is determined by the use of precision CNC machining to establish a niche opportunity. Once high demand levels are confirmed, you can shift your machining to full-time production mode. Besides, precision engineering gives prototypes the chance to poses functional parts.

- Product Uniqueness

Precision machining allows for the manufacturing of customized parts. A lot of customers have ideas or concepts of what they want, whereas others are clueless. With this modern manufacturing approach, accurate, sophisticated and unique parts can be produced.

- Minimal Errors

The CNC machines used in precision enhance accuracy. Once you key in the correct specifications precision machining assumes control. Compared to human machining, the error probability is maintained at a minimum. That means precision engineering, will improve accuracy in all stages of production.

Conclusion

Precision machining is on high demand since companies are seeking ways to improve efficiency. Thus, consider working with a CNC precision machining company that can deliver solutions to multiple industries. Must have the ability to manage and program all your projects efficiently. The economic market is competitive, and companies need to understand the importance of precision machining and maximize its benefits.