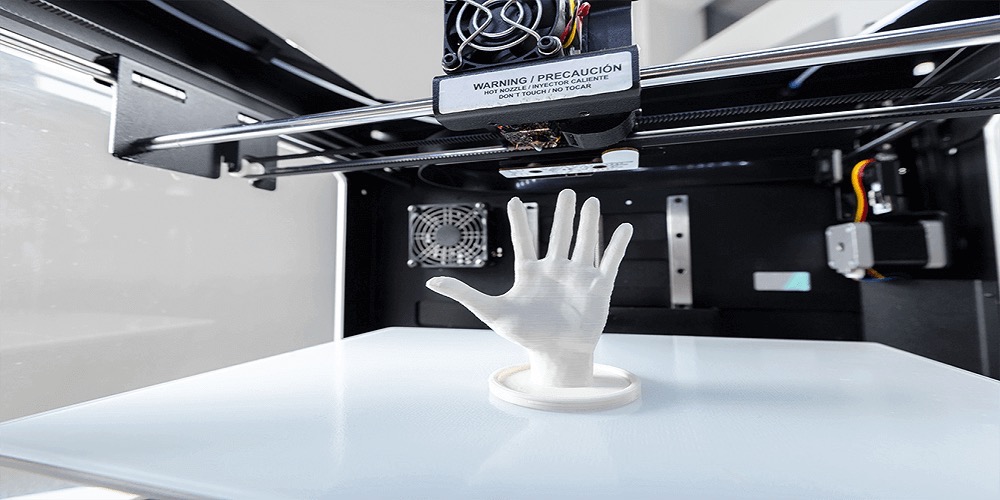

The process of creating a prototype can be very slow and quite expensive. However, it is refreshing to note that there are certain techniques that you can use to optimize the process of developing your product. These techniques will help you produce top-quality prototypes at a lower cost. To get the most out of developing your prototypes, you should consider 3D prototyping. When you use 3D printing to develop your product, you’ll have a lot of 3D printing materials available for you which can help you save money and time.

This article will help you see the numerous benefits of using 3D printing prototypes. You’ll get to see all the reasons why you should implement the use of 3D printing in your manufacturing processes.

4 Major Advantages of 3D Printing Prototypes

1. You can create several iterations of your design

Compared to other manufacturing techniques, 3D printing gives you more freedom when designing. When creating an object from a digital 3D model, using 3D modeling software, you can create numerous desired designs. Your designs can range from simple designs to intricate designs. 3D printing allows you to create any project from scratch. You can always adjust your 3D model anytime you want to.

3D printing allows users to print their 3D models to create either a prototype or a final product. The prototyping process is also easy and convenient. This is because you can create different iterations of your project such that the prototype will be just what you want for your final product.

2. You’ll get to save a lot of money

3D printing is much cheaper compared to other manufacturing processes such as injection molding. One major reason why that is so is that you do not need a mold to create your object. Instead, you can simply create different iterations of your project. This makes saving money easier because 3D printing is straightforward and it gives you what you need. This is an advantage to companies because they’ll get to save so much money.

3. You’ll also save a lot of time

3D printing allows you to create as many iterations as possible and the process of creating the iterations you need is significantly faster than other manufacturing processes. Unlike other manufacturing processes which involve the creation of a mold and waiting for the injection molding process, 3D printing ignores all these steps and makes things easier. This manufacturing process is effective when you want to make rapid prototypes. Generally, with 3D printing, you get to finish the product development faster than other manufacturing techniques.

4. You can also run tests with functional prototypes

Various 3D printing materials are now available in the market. Many of these advanced 3D printing materials are meant for production, but they can alternatively be used for your prototyping process. So, if you want to run a few tests, you can use these advanced 3D printing materials to create useful and beneficial functional prototypes. Their impressive properties will provide all you need to manufacture advanced prototypes.